Warehouse Management

One of the most important activities in a company is certainly warehouse management. It is a complex activity that can only function well if it is organised. Good practice can bring many benefits, such as increased economic revenue and savings in management costs. Many are the right people who, through their activity, allow to manage this aspect of the company correctly. Conversely, an unorganized warehouse can also be a source of trouble in your business.

But how can we understand how this aspect of the company affects our work? A poorly managed warehouse can mean delays in the time taken to process orders, generating dissatisfaction in the customer who will not be satisfied and who will certainly no longer choose the company that has created problems with the delivery of goods. This may not be the case with a good organization.

But how can you organize your warehouse? The three reference points to follow are:

the organization of personnel, warehouse logistics and the drafting of correct documentation that will accompany the goods.

Types of documents relating to the warehouse

Managing a warehouse also means dealing with the documentation that accompanies the goods, so to do this job properly, you need to list the essential documents for an ordered warehouse.

The most famous document, also known by those who are not in charge of the work, is the transport document. This must accompany the goods throughout their journey from the warehouse to their final destination.

The invoicing of goods, on the other hand, is all that concerns the tax aspects related to the operations of buying and selling goods. A precise invoice is important for the performance of the loading and unloading of goods in the inventory.

Storage personnel

For a good organization it is also necessary to adequately train the warehouse personnel for their work. Never neglect order. This is a fundamental principle which, if respected by all workers in the sector, brings benefits. Order is maintained when all operators carry out their duties precisely and punctually.

In this field improvisation is forbidden because any error negatively affects the business of the company. Therefore, every warehouseman must know his precise task, which he can never delegate to another, and must shirk his responsibilities in the event of an error.

The tasks of each warehouseman should be indicated from the outset and it will be right to appoint a warehouse manager to coordinate all activities and provide clarification to colleagues.

A good storage company must perform tasks relating to the receipt of goods. You will have to take care of receiving the incoming goods, check the correspondence of the documentation that accompanies it and the condition of the goods, free of any damage or defect.

The storage of goods concerns the movement of the goods from the reception area to the “storage area” where each load will be placed, according to criteria established with the person in charge. The drafting and control of the inventory concerns the knowledge of all the goods in the warehouse and where it is placed.

The warehouse staff are also responsible for the organisation of the shipments. This operation is coordinated by interfacing with the couriers.

Inventory – how and when to do it

When it comes to inventory, it means identifying and classifying what is in the warehouse at a given time. This is an essential periodic activity for the company. With this activity, the inventories of goods in stock will be calculated and the assets present and intended for sale verified. The closing balances are then calculated and grouped into homogeneous categories, distinguished by nature and value.

With the inventory you can understand which goods are to be bought back and which are not. The cost of fungible assets is determined using the calculation of the weighted average cost, known as the Lifo method, which means first income and first income. We can also base ourselves on the Lifo method, where we mean the first person to enter and the first person to leave.

The useful advice in case of inventory, will be to develop written reports containing the indication of the type of product, its code and the calculation of the units that are consumed in a year, using a special software.

Inventory is considered an obligation for the holder of a stock and is important to verify that inventories correspond to the bookkeeping entries in the holding’s balance sheet. Companies, partnerships, natural persons running a business, public and private commercial entities are obliged to carry out such operations.

Those who are exempt from the obligation to inventories can only do so to ascertain stocks in the warehouse, establishing how much goods there is, organize future procurement activities or assess whether some goods should be excluded from the production cycle.

Once the physical account of what lies in the warehouse is complete, the value must be assigned in the cost items of the company’s operating result. The inventory requires some commitment and attention, since in addition to the physical aspect concerning the presence of goods and their procurement, a physical evaluation of the goods remaining in stock must also be made. This makes it easy to assess the development of business or production.

Warehouse security (Cleaning, ordering, security systems)

Warehouse safety is a fundamental principle that allows the guarantee of an optimal state of all the components present, which prevent risks concerning people, interruption of services and possible damage to goods. It is important to ensure a certain security to minimise any type of risk. For this reason, it is good practice to plan a good training, prevention, maintenance activity and to use safety systems to protect the goods present.

To guarantee safety in the workplace, it is essential to take part in training activities on the subject, which are able to involve and motivate the staff. With good training, risk prevention is possible. Therefore, preventing occupational accidents by using safety measures appropriate to the working environment is important. Identify the risks in the warehouse, evaluate them and prioritize them, plan the measures needed to prevent them, adopt them and monitor the situation.

For its part, the company must guarantee all its employees, including those in the warehouse, the good condition of the equipment, safety in the workplace and well-being in the environment. So it will have to be verified the condition of the racking that contain a number of products for each level and comply with European standards, elevators, lighting, cleaning of corridors and the strength of pallets.

In order to work in safety, it is also important to periodically carry out maintenance activities on everything in the warehouse, avoiding reusing machines or using shelves that do not consist of optimal conditions.

As far as the security systems that can be adopted in a warehouse are concerned, the alarm system designed and installed specifically is important. When we talk about large dimensions, it is good to carry out a proper assessment of the equipment and technologies that will have to be used. You will also have to decide whether you want to divide up your areas into warehouses or rely on a single solution.

A good protection system for a warehouse should be composed of an alarm system appropriate to the factory. There must be access control and management. This way it is possible to manage multiple accesses and authorizations, monitoring the personnel and vehicles present both outside and inside the company. This could be done with video surveillance systems or with 24-hour operational surveillance. It will also be important to have a continuous self-diagnosis system, which does not allow false alarms to be incurred.

Training of warehouse staff

As we have already said in the section on safety, training warehouse personnel is important, both from the safety and from the work point of view. It is important to organise courses that motivate and stimulate the worker to do more and better, providing him with the necessary tools for good training in the profession.

Periodic maintenance of equipment

To keep your warehouse safe, you must comply with the European regulations on shelving and the means used for safe working.

Everything in the warehouse must be well maintained. Space must be well divided to allow adequate passage of goods transport equipment such as forklifts and pallets. These must have a good gap between one shelf and another and these must always be well divided by shelves, taking into account the maximum load they can hold. Periodically, maintenance work must be carried out by the company that supplies the shelves and vehicles and, if necessary, communicating the need to change everything.

Logistics (what is it and why it is important for the warehouse)

Logistics in the warehouse are important. Therefore, it is important to consider different aspects, such as physical management and information, as well as the organization of the product flow. In this case, the logistics aspect is important for optimal warehouse organisation.

To have an optimal logistics, the goods must be disposed of according to the correct storage methods, since the lack of order could generate an increase in costs and waste of space.

It is always good to avoid maintaining accumulations of goods where there are areas of passage, as the inability to meet the needs of the end customer creates a state of dissatisfaction and bad publicity for the company.

Having control data is necessary to obtain statistics backwards in time, monitoring performance.

For this reason, it will be necessary to be able to organize the warehouse in the best possible way, both structurally and organizationally, using a good development strategy based on the focusing of realistic objectives that are realized to optimize. An incremental strategy must be followed that allows to confer procedures that give order and practicality to the company. This reduces the cost of storing goods and the time required for handling goods.

Reordering of goods (as established by the reordering of goods)

The reordering of the goods is only possible by using suitable means that keep order in the warehouse. This is an order concerning the goods that have been processed and those that have arrived in the warehouse. You must reorder the stocks when you touch the minimum point of presence of goods in the warehouse.

It is important to avoid ordering goods unnecessarily, as overloading them could create inventories that are difficult to place in the future and above all create excessive costs, since the goods in stock also generate unnecessary costs that can only be avoided by correctly planning orders.

Classification of products in stock

Products should be classified according to the order of sale. The more a product is sold, the more its position in the room where the goods are stored will have to advance. It is important to always have the best selling products available to quickly process your order and create satisfaction in delivery times, in customers who will return to choose a certain company because of the speed.

Calculation of the costs of stock maintenance

The real cost of managing the warehouse is important because there are many factors that determine it and it goes beyond the question regarding the cost of goods sold and raw materials. You can subdivide the costs of stockholding relate to capital costs or financing charges, storage costs and service and risk costs.

Capital costs are any expenditure related to investments and interest on operating capital, not to mention the opportunity costs of money invested in inventories.

Storage costs, on the other hand, concern everything related to the maintenance of the building’s installations and the building itself. If you are in the situation of saturation of the space available in the warehouse, the additional costs will not be long in coming.

Service costs will be insurance, hardware and software, while risk costs relate to the fact that items lose value when in stock. This case concerns perishable goods.

Dropshipping. What it is and how it works

Drop-Shipping is a true digital sales model. This is based on the synergy between the manufacturer who supplies those who manage an online e-commerce store that in turn sells the goods to the end user, the network’s customer. Drop-Shipping was considered an opportunity to make a profit because the producers only make and ship the products, without having to worry about sponsoring and placing them. Those who sell, on the other hand, focus only on developing good marketing that attracts as many customers as possible. The buyer finds a lot of choice in the e-commerce site and for this reason he finds this type of offer more interesting.

It is convenient to use dropshipping because there is no substantial use of capital but there is only the use of the initial one. This consists of opening the e-commerce store. The supplier who receives the order and the money to buy the goods, will only have to send it to you since it will be the end customer to pay. Whoever manages the e-commerce portal will not have to buy goods and therefore will not need to have a warehouse. It is an easily manageable business. Only a good internet connection will be needed to monitor the market trend and the demands to be made on the manufacturer.

There are many sales and purchasing possibilities because you can contract with different brand suppliers without having to manage your warehouse. The possibility of contacting foreign suppliers can also be considered if it is considered that there is a good value for money.

Stock surplus and strategy to avoid stock surplus

If there are excessive inventories, a good plan must be followed to avoid running into this situation all the time. It is good to identify the reasons why there is an article that remains in stock for too long and then a way to get rid of them by making the most profit. It is advisable to rely on promotional sales or stocks that will avoid the stock of unsold goods for a long time.

To avoid having surplus stock of goods, it is always good to buy a certain item when necessary, which is sold more easily, monitoring the market.

Tracking of all goods

There must be constant traceability of goods from when they arrive in the warehouse to their dispatch and use. This is important for the inventory. You can track the goods physically through inventory, too, and this is considered a major resource use periodically.

By carrying out random checks, it will be possible to select only a part of the goods. This operation, which is carried out periodically, allows you to get the pulse of the situation and lighten the annual work.

The rotational inventory is made at least one day a week. This records deviations and reconciles the physical and accounting stock. This is easy to do using barcode readers, which avoid errors and save time.

Statistics forecast

It is good to make statistics that allow you to make a forecast about the demand for goods in stock. This operation has several variables, although it is possible to use some tools to make a good accurate forecast. It is good to compare sales with the same period of the previous year and check the growth rate on a period-by-period basis. Sales already made under contract should be taken into account and, given the season or holidays, market trends should be taken into account. Plan promotions and scouting periods when necessary.

Contingency plan

Even if you are in a rosy period, it is always good to know how to prepare for the worst, because warehouse management can also become dangerous. When you experience anomalous situations that you cannot cope with or if there is a delay from a supplier, you should know how to speak up. In this case, risk factors of any nature must be identified, finding a solution to the critical issues. Employees will also need to be made responsible to ensure that a problem can be prevented rather than addressed.

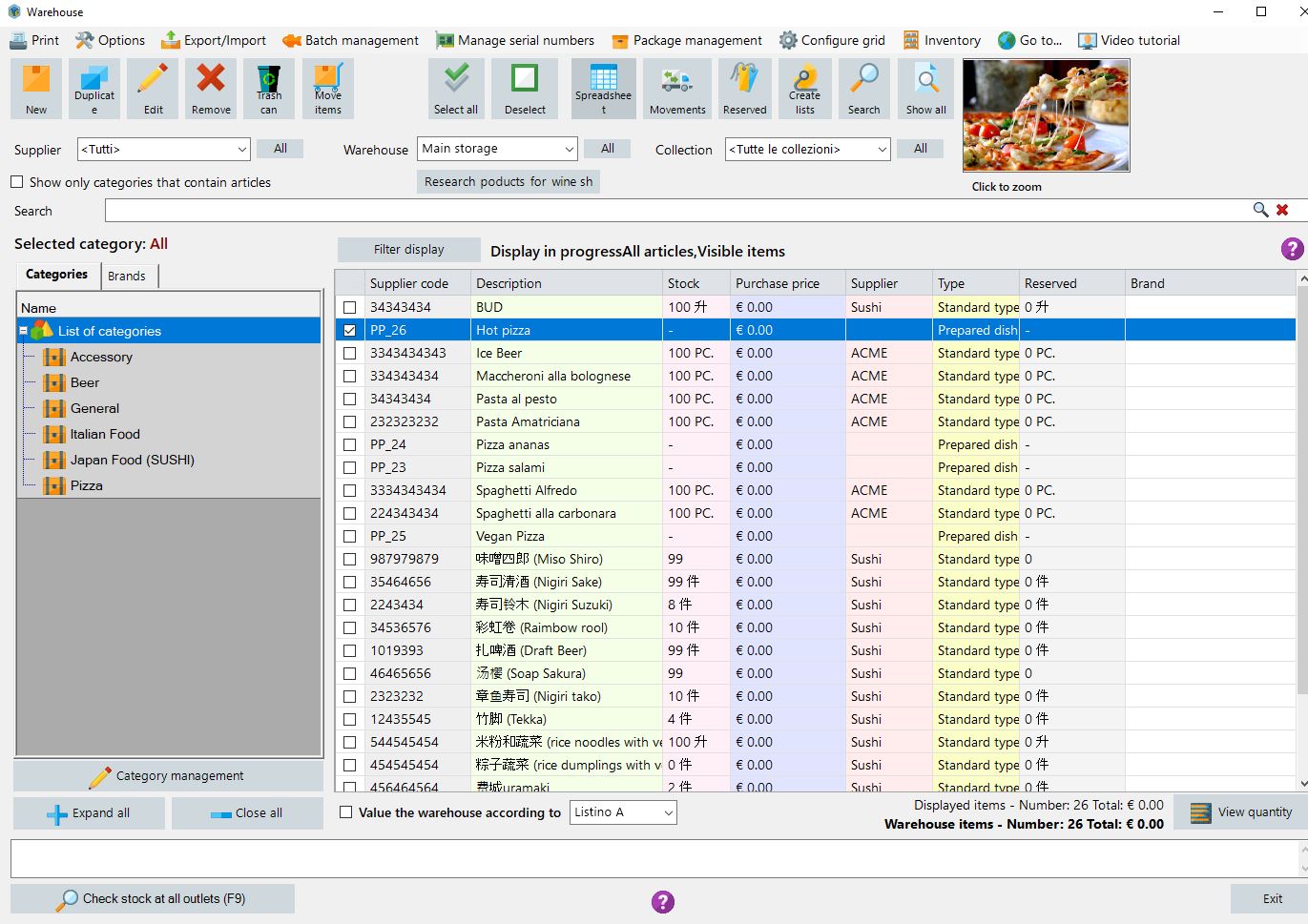

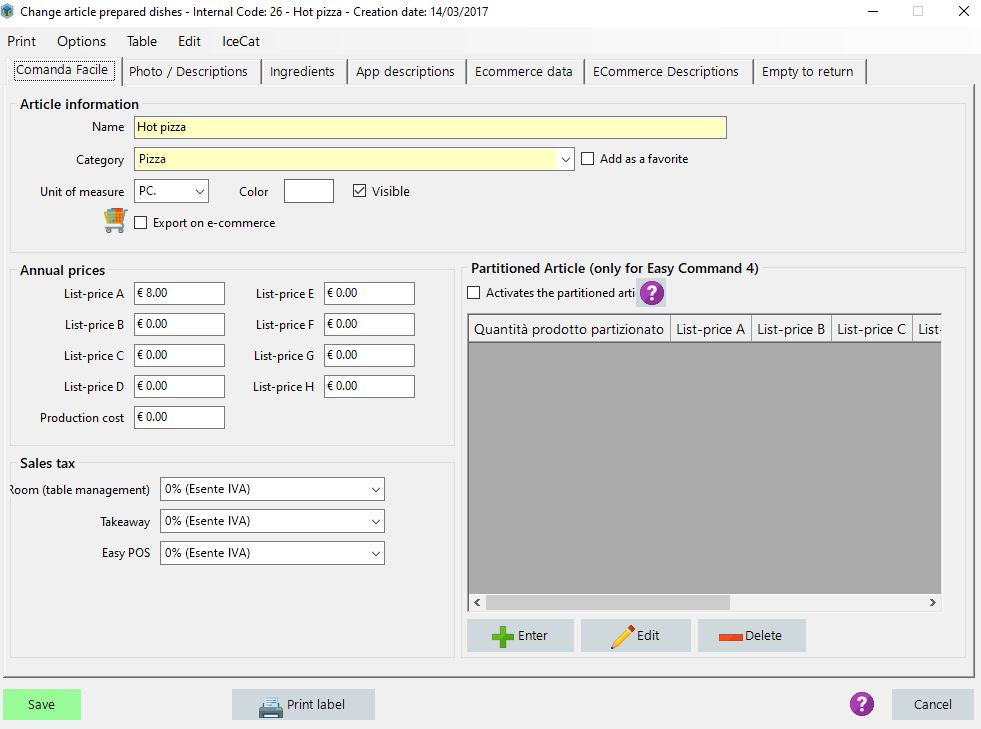

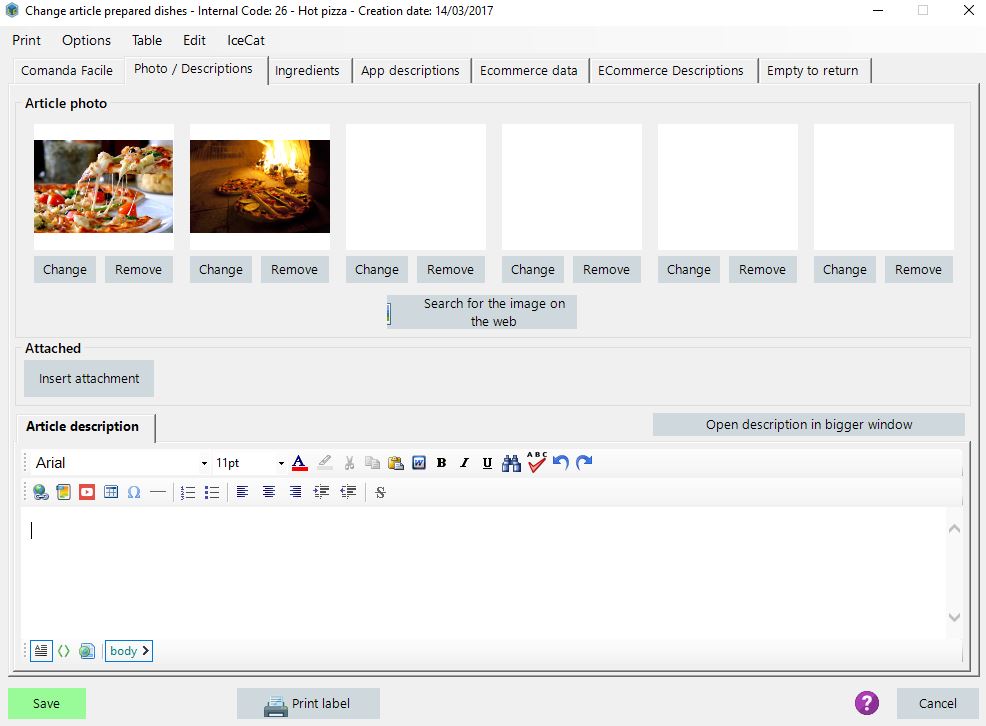

The importance of using good management software such as LibertyCommerce

To better manage your warehouse today it is necessary to use management software that can provide accurate and fast management of the warehouse. It is advisable to opt for this solution to always have the stock count, stocks and reorders under control. The software can also calculate the reorder estimate or give you the information you need to do so, as well as manage loading and unloading. With the software you can have the history of movements and simplify inventory operations.

LibertyCommerce is a management software able to adapt to any type of medium or small business. Installing and using it is easy, just download it, register and you’re done. This way, your warehouse can always be well managed without any problems.

The libertycommerce warehouse also interfaces with the “LibertyScan” app for IOS and ANDROID, which allows easy management of logistics by compiling lists of items to be inserted in any type of document.